The best for electronic board testing

Unbeatable in throughput and fault coverage

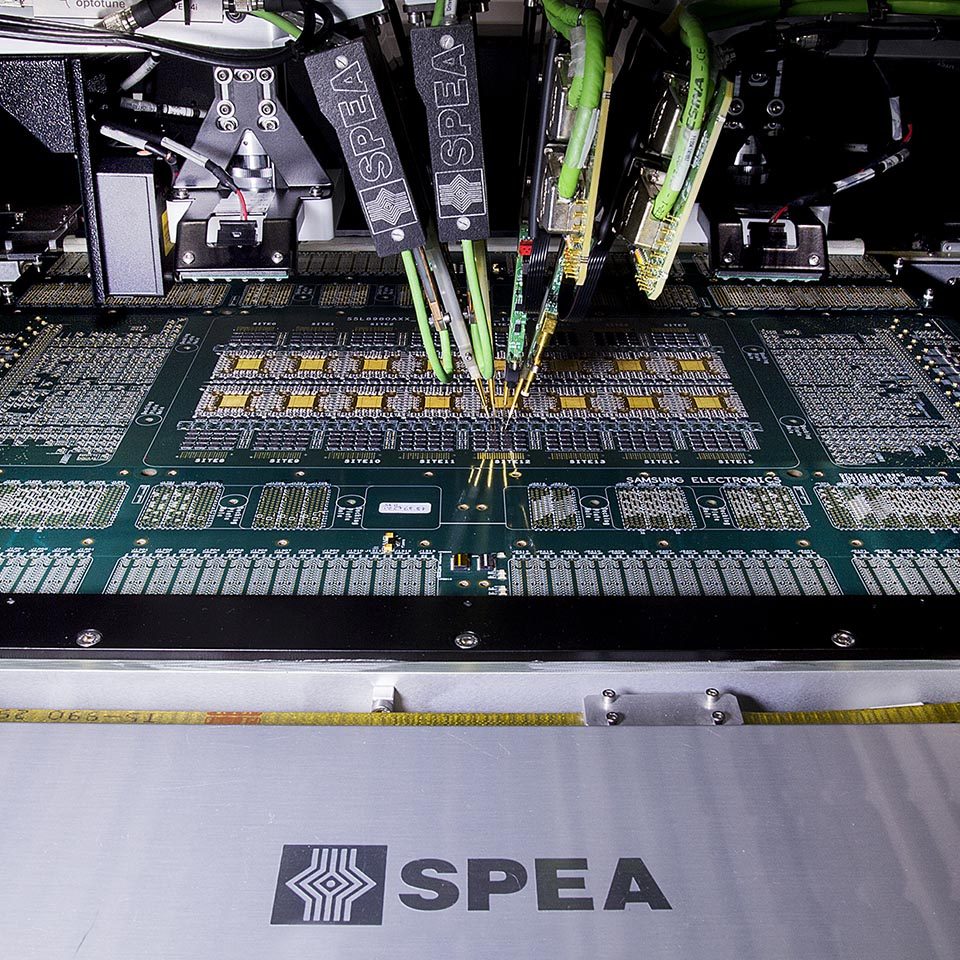

SPEA automatic flying probe testers for electronic boards stand out for their unsurpassed throughput performance and for their excellent fault coverage.

The main advantage of flying probe testers is that they are immediately ready to test every new product, without needing any specific interface fixture or testability study.

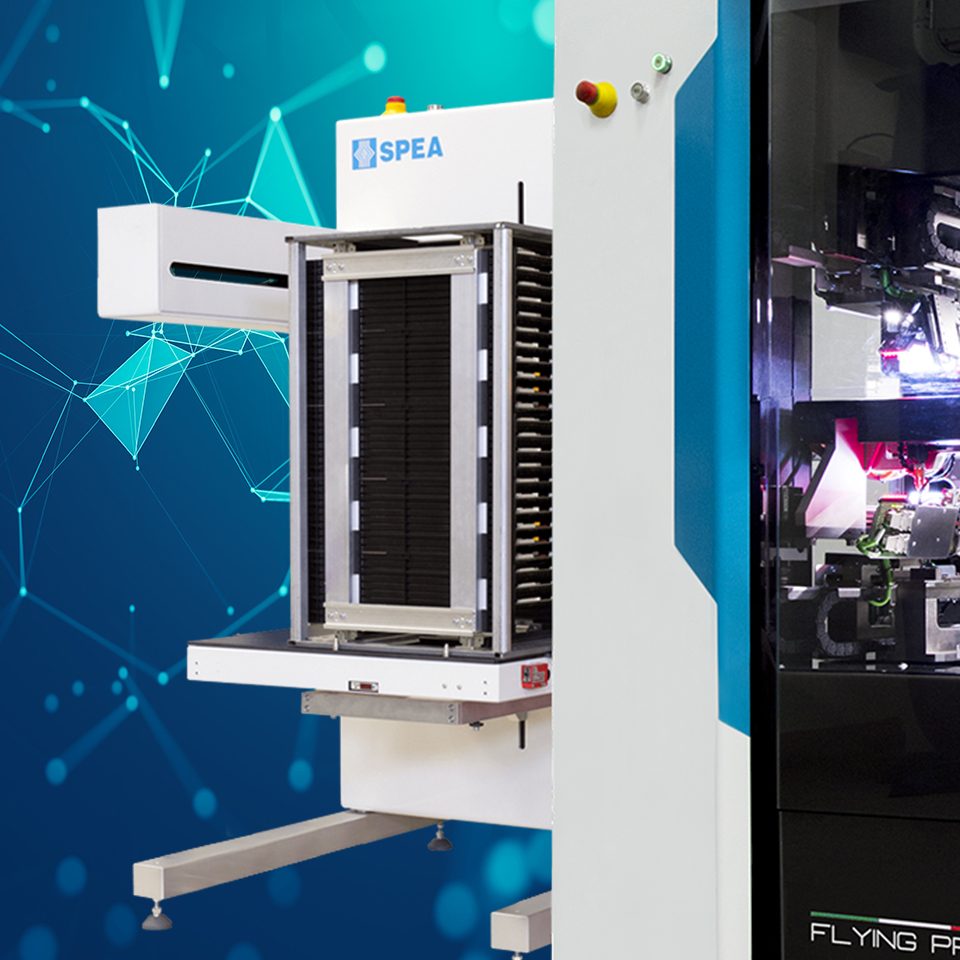

To this feature, SPEA systems add complete automation both in test program development and in system operation. Starting from CAD files, the generation of an in-circuit test program is completely automatic, as well as the fine-tuning and stabilisation of the measurements: in a few hours, the test program is ready to run. The tester operation can be completely automatic, without any operator’s intervention: with the aid of SPEA Board Handling Equipment, the flying prober can run over an entire work shift or a weekend in full autonomy.

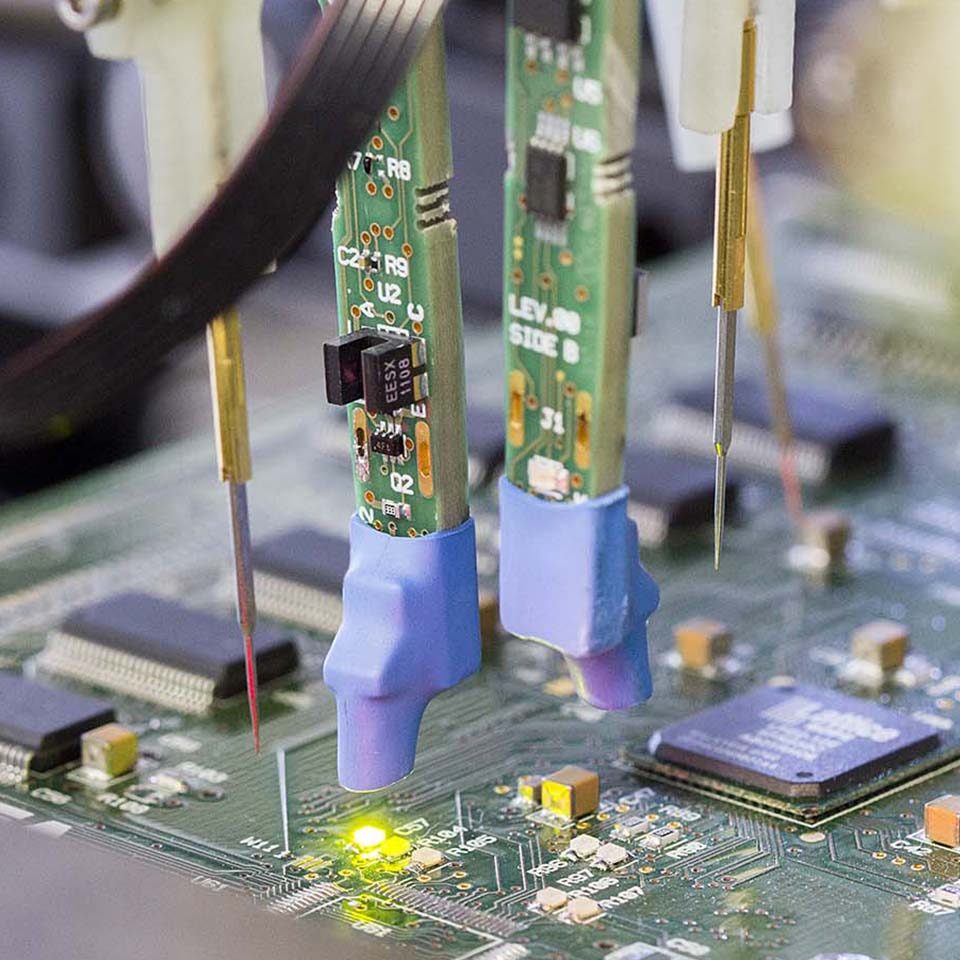

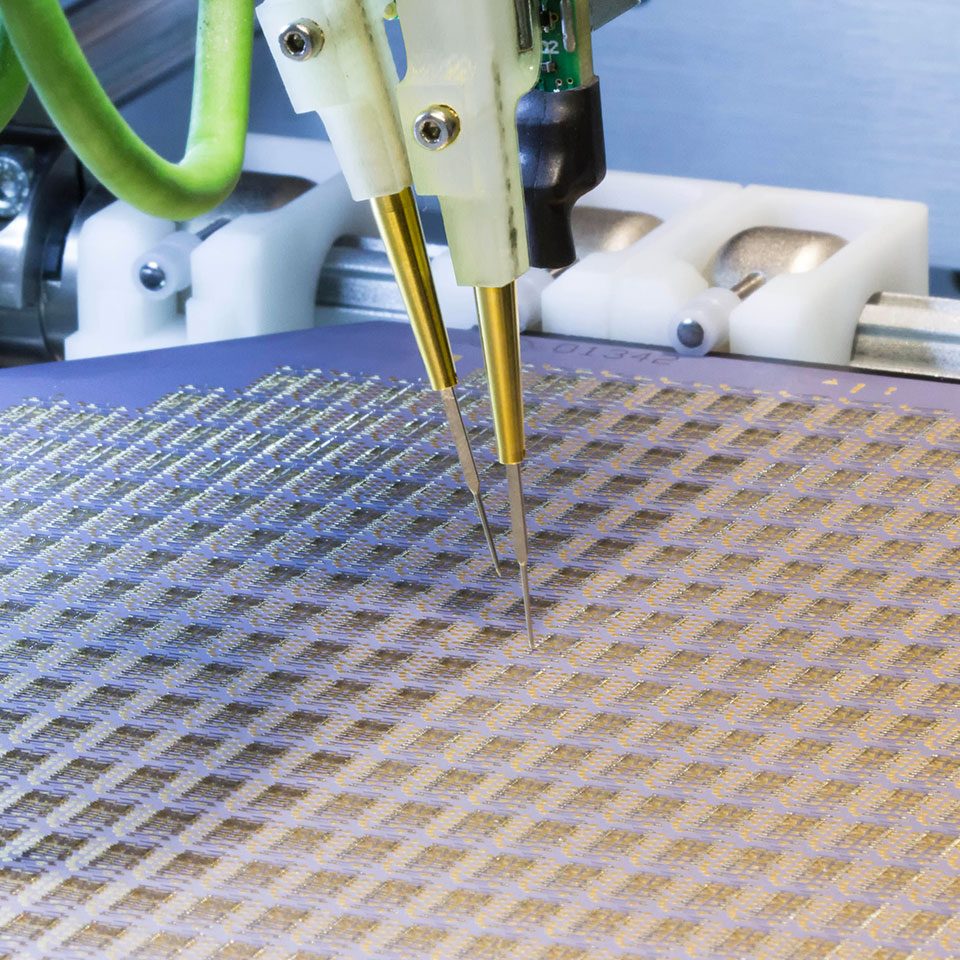

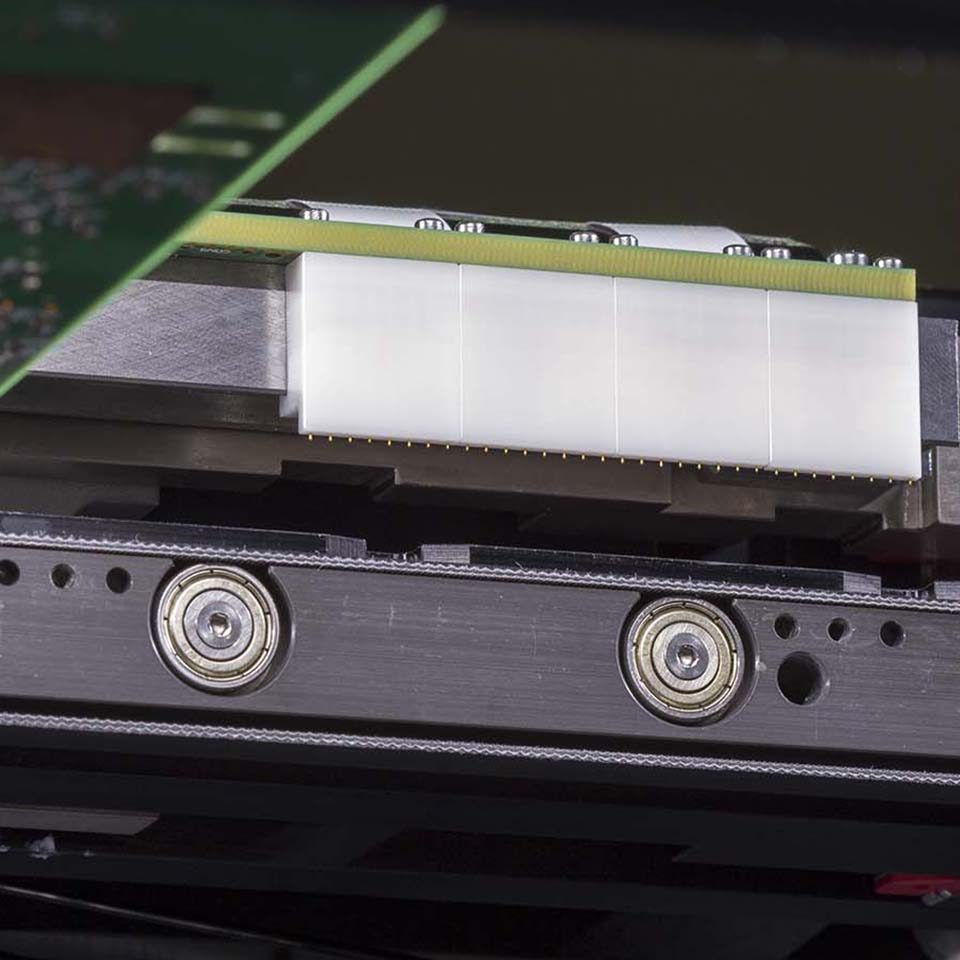

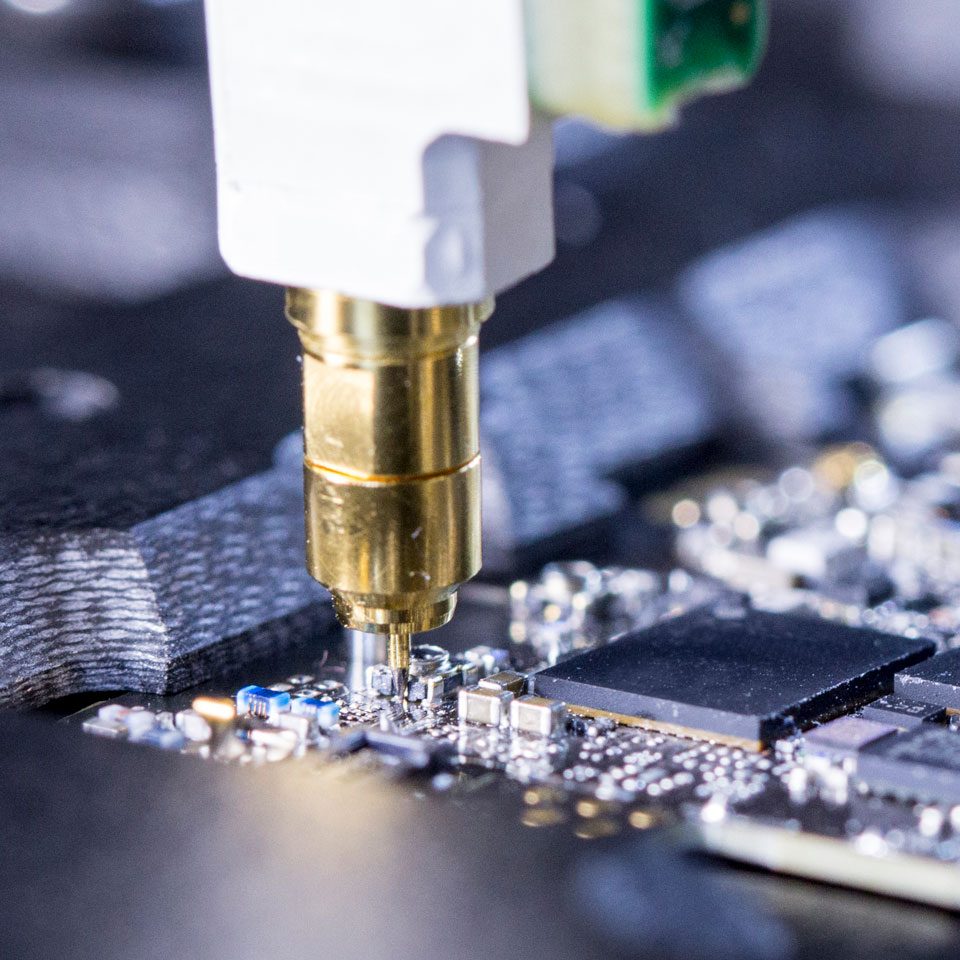

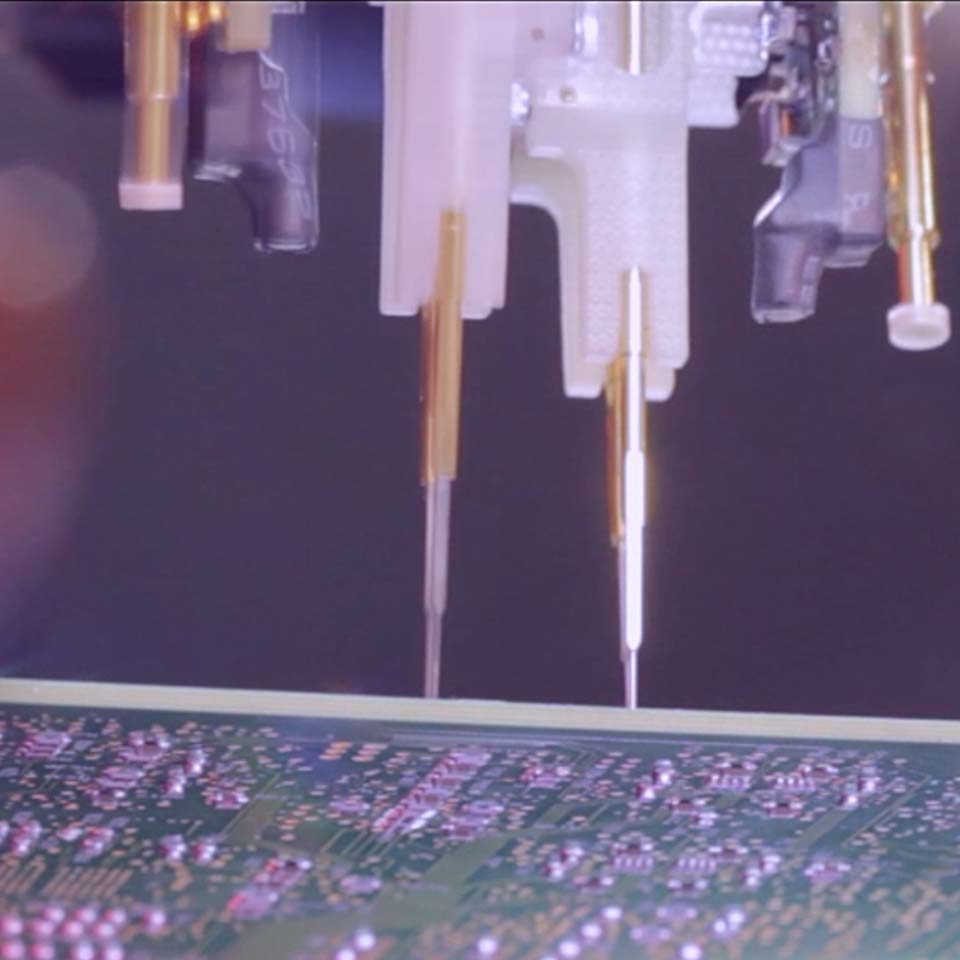

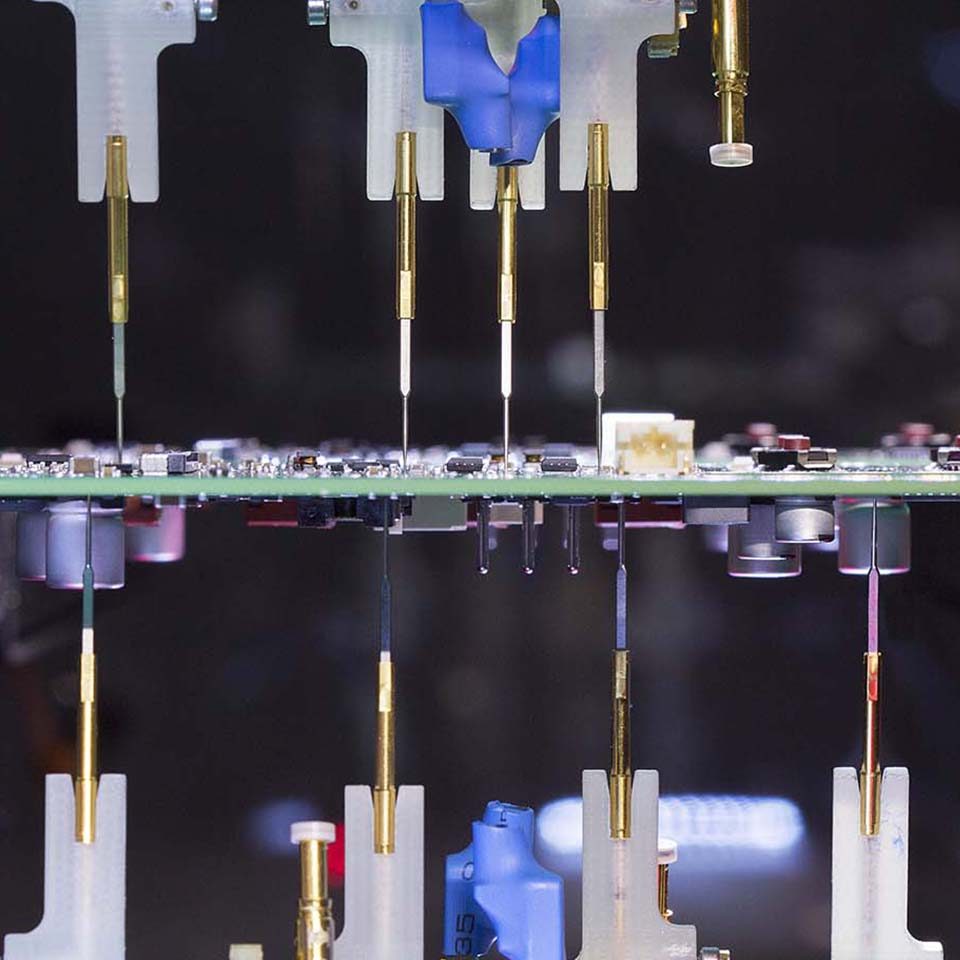

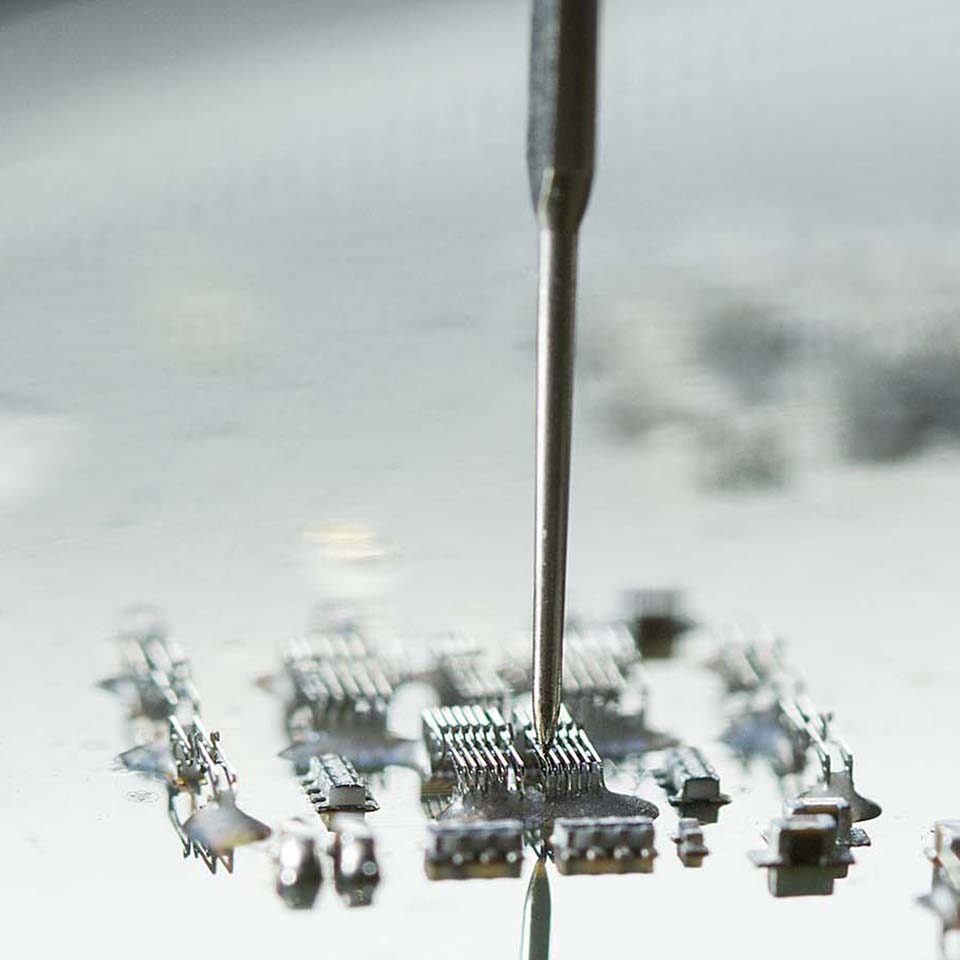

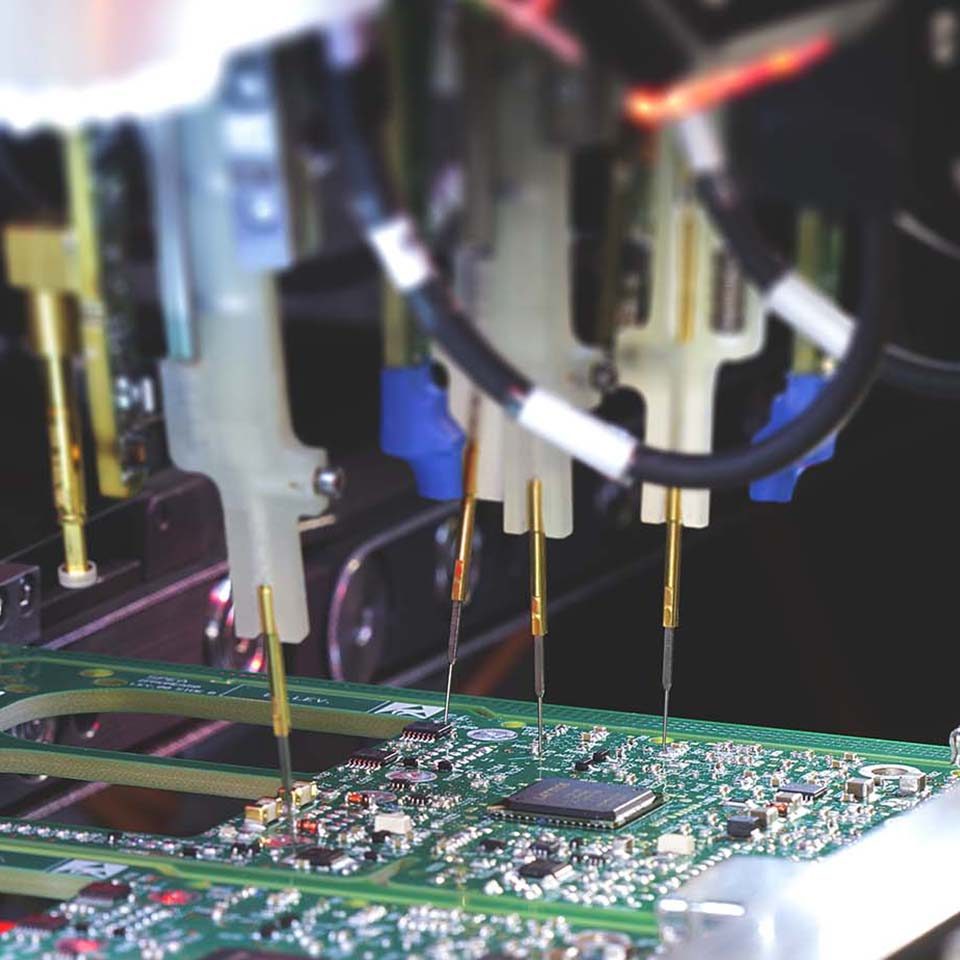

Ultra-fast probes are able to contact points as small as 30 µm and, therefore, they can directly contact the pins of the smallest components on the board: it is no longer necessary to include special test pads in the printed circuit board design. This accuracy is stable over time, thanks to linear optical encoders in XYZ which give continuous feedback on the real probe positioning, with a resolution of 12 nanometers.

Moreover, the motion profile of the probes avoids the risk of damaging the contacted points, for a zero-impact contacting also in case of multiple probings on the same point.

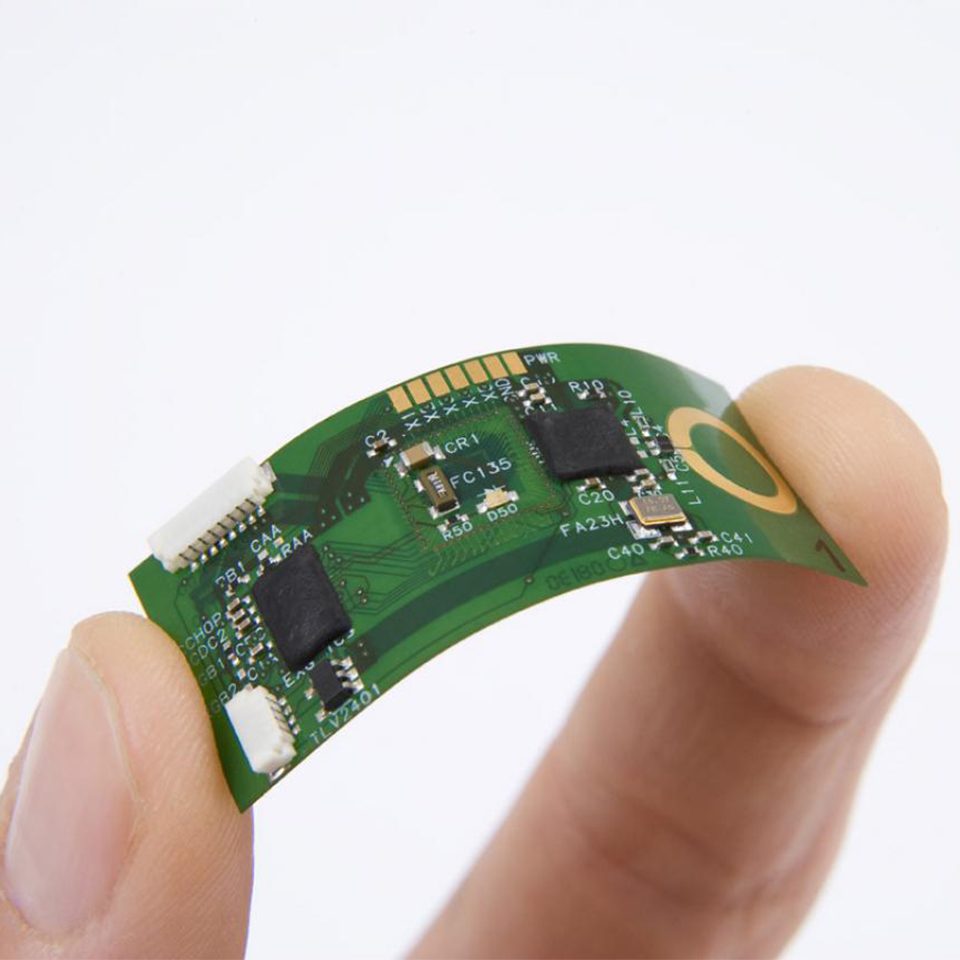

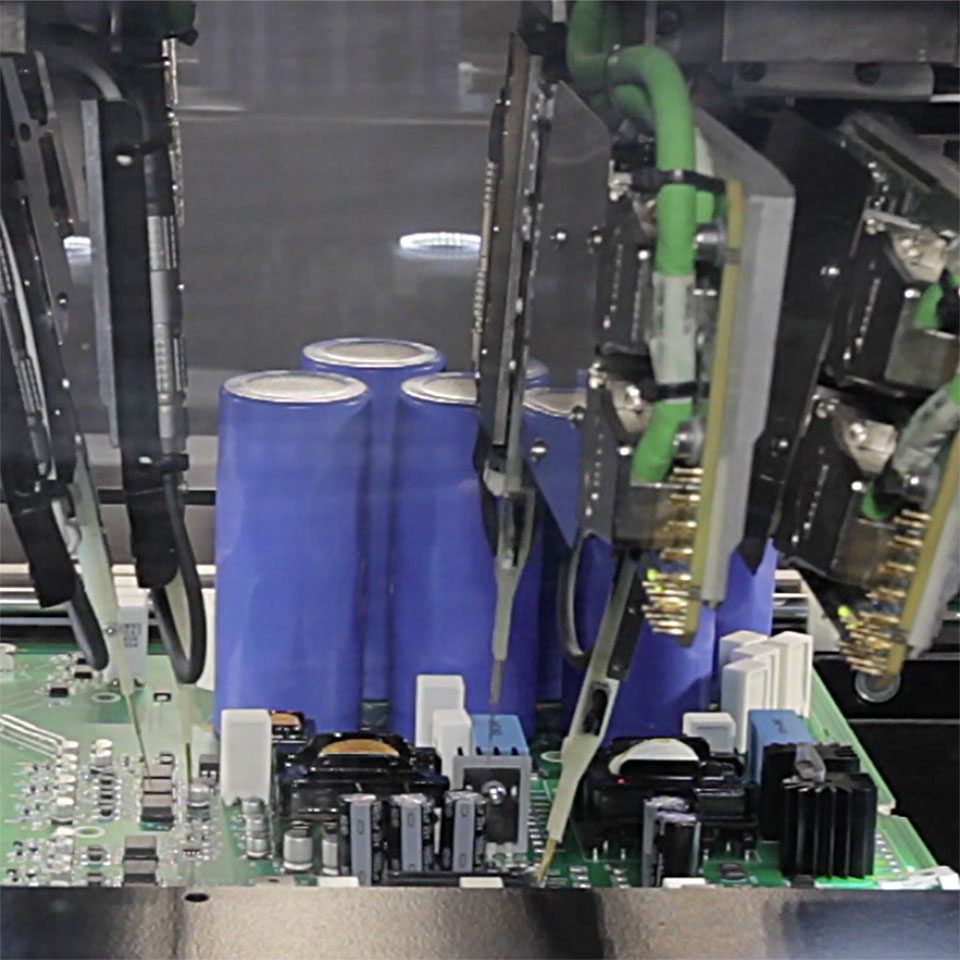

SPEA flying probe series includes different models, so as to cover different production needs from high volumes – over 800.000 boards per year – to low volumes, to NPI and prototypes. Every model can be equipped with different modules and tools to test different products such as electronic boards, flexible circuits, power modules, back planes, semiconductor test load boards and probe cards, ceramic devices, microelectronics and silicon wafers.

Top Features

Unparalleled throughput

Unparalleled throughput

Over 800,000 boards per year

SPEA designed and manufactured the first automatic flying probe tester with a very high throughput.

Ultra Positioning Accuracy

Ultra Positioning Accuracy

Even on micro-pads and SMD 008004 components

SPEA testers are engineered to meet the testing needs of new microelectronic technologies.

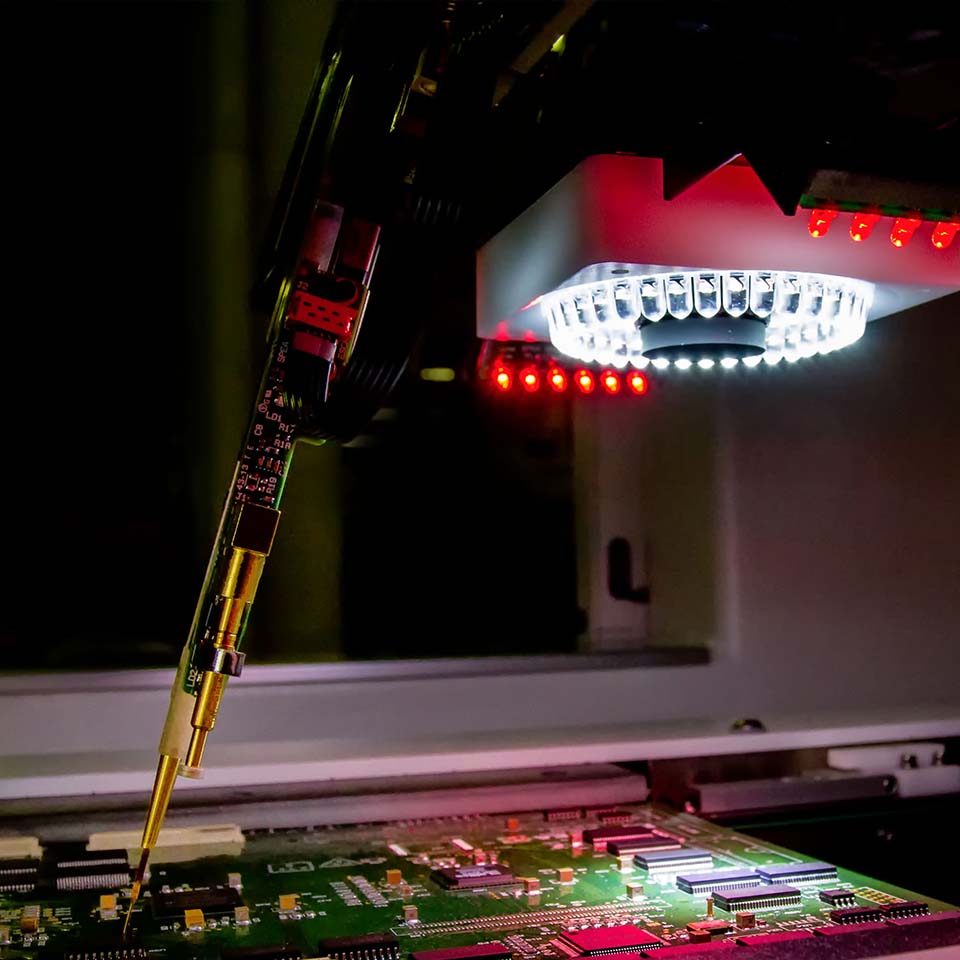

No Damage Touch

No Damage Touch

Controlled-force probing

The smallest and most delicate test pads require a controlled motion profile for the flying probes.

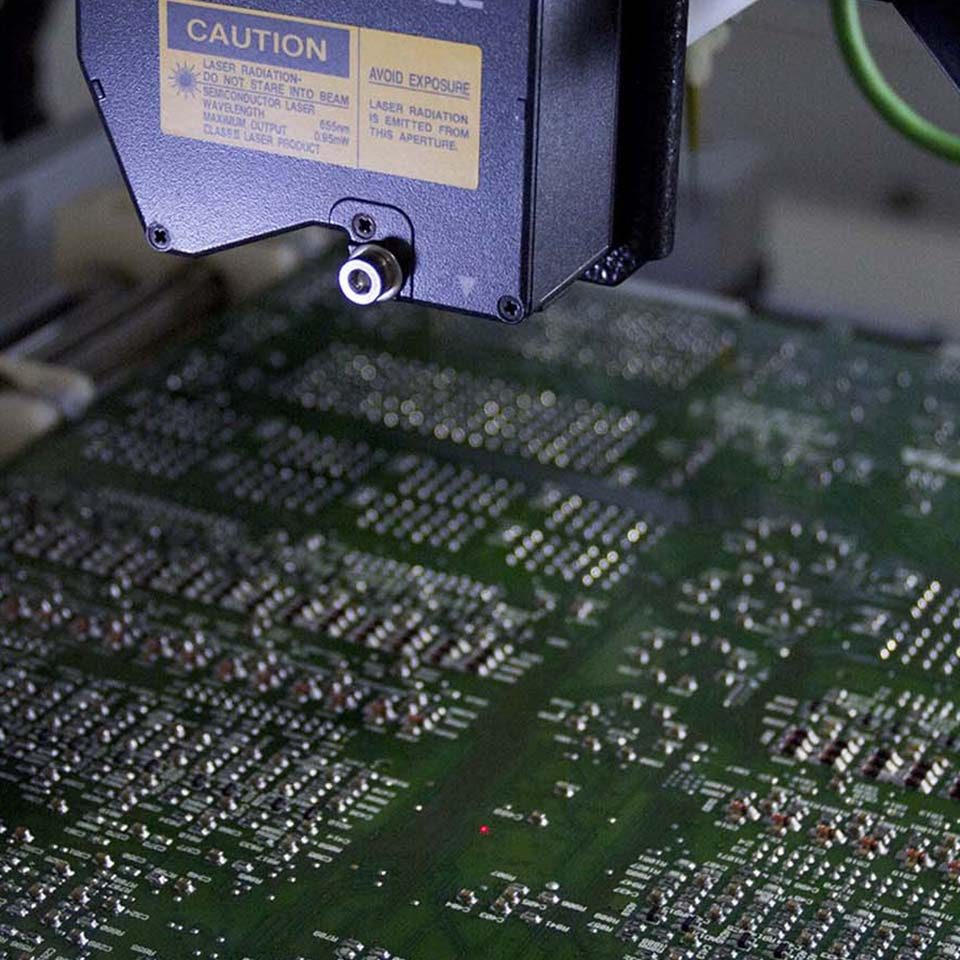

Short Circuit Test on all nets

Short Circuit Test on all nets

Even on high-density boards

Electrical measurements on all nets allow to identify all short circuits.

Automatic Board Handling

Automatic Board Handling

Minimum footprint, maximum efficiency

Discover how to maximize your test throughput and to ensure the continuity of your test process.

Intuitive software

Intuitive software

Maximum ease of use

The users can operate easily, through intuitive graphical interfaces, within an app-based software environment.Find the right tester for your needs

Compare Flying Probe models

| 4080 | 4080X | 4085 | 4060 | 4050 | 4020 | |

|---|---|---|---|---|---|---|

| THROUGHPUT | ||||||

| UPH (UPY) [340 net - 357 components] | 128 (1 Mln)* | 128 (1 Mln)* | 128 (1 Mln)* | 83 (660 k)* | 47 (372 k)* | 31 (246 k)* |

| UPH (UPY) [1000 net - 600 components] | 63 (500 k)* | 63 (500 k)* | 63 (500 k)* | 41 (330 k)* | 34 (270 k)* | 22 (180 k)* |

| ⠀ | ⠀ | ⠀ | ⠀ | ⠀ | ⠀ | ⠀ |

| PROBING | ||||||

| Top Flying Heads | 4x | 4x | 4x | 4x | 4x | 4x |

| Bottom Flying Heads | 4x | 4x | 4x | 2x | - | - |

| Bottom Lift | - | - | - | - | 1x | 1x |

| Contactable pad (min) [µm] | 30** | 50** | 30** | 70 | 70 | 70 |

| ⠀ | ⠀ | ⠀ | ⠀ | ⠀ | ⠀ | ⠀ |

| AUTOMATIC LOADING | ||||||

| From Rack | Yes | Yes | Yes | Yes | Yes | Yes |

| From Conveyor/Line | Yes | Yes | Yes | Yes | Yes | Yes |

| ⠀ | ⠀ | ⠀ | ⠀ | ⠀ | ⠀ | ⠀ |

| DIMENSIONS | ||||||

| Dimensions [WxLxH] | 1700 x 1300 x 2050 mm 67 x 51 x 81 inches | 1700 x 1438 x 2080 mm 67 x 57 x 82 inches | 1285 x 1000 x 2063 mm 51 x 40 x 81 inches | 1750 x 1272 x 1724 mm 69 x 50 x 68 inches | 1600 x 1220 x 1660 mm 63 x 48 x 65 inches | 1600 x 1220 x 1660 mm 63 x 48 x 65 inches |

| UUT Size (max) [LxW] | 1000 x 460 mm 40 x 18 inches | 1000 x 460 mm 40 x 18 inches | 500 x 190 mm 20 x 7.5 inches | 1524 x 610 mm 60 x 24 inches | 1000 x 400 mm 40 x 16 inches | 1000 x 400 mm 40 x 16 inches |

| Device Height (Top/Bottom) | 85/85 mm 3.4/3.4 inches | 150/150 mm 5.9/5.9 inches | 45/45 mm 1.8/1.8 inches | 80/55 mm 3/2 inches | 55/90 mm 2/3.5 inches | 55/90 mm 2/3.5 inches |

| Flexible Circuit on Reel Width | 190 mm 7.5 inches | 190 mm 7.5 inches | 190 mm 7.5 inches | - | - | - |

| * 8h, 3 shifts, 330 days | ||||||

| ** In ultra-accurate probing configuration |